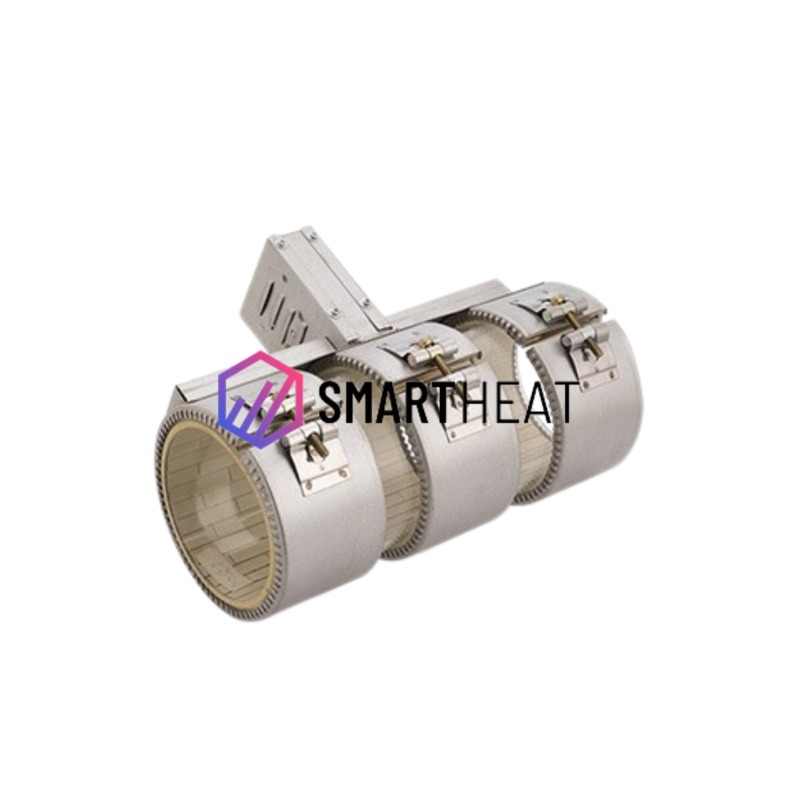

Hot Runner Heater

Pemanas Koil (Coil Heaters) paling sering digunakan untuk mesin injeksi atau cetakan plastik. Pemanas koil dirancang untuk melelehkan plastik dalam cetakan hot runner. Desain pemanas koil memungkinkan perpindahan panas secara 360 derajat, sehingga memastikan perpindahan panas yang optimal di dalam cetakan. Untuk mendapatkan bentuk pegasnya, pemanas koil dipanaskan dan kemudian didinginkan secara perlahan agar dapat dibentuk. Meskipun ada sedikit spring back (kembali ke bentuk semula) yang terjadi, biasanya hanya sekitar 0,001-0,002 inci dan dapat dikoreksi dengan membentuknya menggunakan mandrel yang berukuran lebih kecil. Pemanas ini dapat menghasilkan hingga 106 Watt per inci persegi dan mencapai suhu operasional hingga 1200 derajat Fahrenheit atau sekitar 649 derajat Celsius.

Berbeda dengan cartridge heater, pemanas koil dipasang mengelilingi nozzle hot runner tempat plastik mengalir melalui koil, sementara pada cartridge heater, plastik mengalir di sekitar area yang dipanaskan. Pemanas koil juga dirancang tidak hanya dalam bentuk radius konvensional, tetapi juga bisa datar, yang memungkinkan perpindahan panas yang lebih tinggi ke logam dan material termoplastik. Kedua jenis pemanas ini terbuat dari baja stainless 430 dengan ketebalan sekitar 1/4 inci.

Pemanas koil juga dirancang untuk memiliki berbagai gaya dan sudut keluaran agar sesuai dengan rongga cetakan apa pun. Seperti pemanas lainnya, pemanas koil dapat dilengkapi dengan termokopel tipe J atau K internal untuk mengukur panas secara akurat, sehingga kontrol pelelehan plastik yang stabil dan merata dapat dicapai. Selain itu, berbagai jenis kabel dan selubung dapat diterapkan. Untuk suhu tinggi, Teflon biasanya menjadi pilihan untuk kabel, dan dapat dilengkapi dengan kabel berlapis anyaman logam atau kabel berpelindung. Pemanas koil memang lebih mahal dibandingkan band heater konvensional, tetapi memiliki umur pakai yang lebih panjang.

Daya dan ukuran dapat disesuaikan dengan kebutuhan Anda. Segera konsultasikan kebutuhan Anda secara gratis melalui WhatsApp dengan tim kami di (+62) 852-1066-5767. Pastikan Anda mendapatkan solusi elemen pemanas yang tepat untuk kebutuhan aplikasi industri Anda. Jangan lupa kunjungi website kami di smartheat.co.id dan media sosial Smart Heat untuk informasi lebih lanjut.